Machine Tool Operator Overview

CVTC’s Machine Tool Operator is a one-year technical diploma. The Machine Tool Operator program provides training for entry-level employment in a machining environment. Students will be exposed to manual lathes & mills, Computer Numerical Control (CNC) machines, Computer Aided Design/Computer Aided Manufacturing (CAD/CAM) workstations, and Coordinate Measuring Machines (CMM). Students will gain the foundational knowledge and skills necessary to operate various machine tools, along with other support equipment, to produce parts to meet print specifications.

This program offers hands-on training from highly skilled and experienced instructors for employment in CNC programming, CNC machining, CNC operation, mold making, and quality-control inspection. If you wish to join the workforce quicker, have strong mechanical skills, and enjoy building or crafting things, this could be the program for you!

The Machine Tool Operator program is an affordable option allowing you to earn your diploma in less time, so you can join the workforce quicker and earn a competitive salary. Plus, graduates from this program often have several job offers when they graduate!

Throughout this one-year program, you’ll learn about:

- G & M code programming

- Cutter compensation techniques

- Casting molding, welding & gluing

- Classification of materials

- Machine tooling terminology

- Engineering language used on blueprints

- Interpretation of blueprints

This program has an advanced placement entry option. Advanced placement is an opportunity for graduates of a related program to further their education. Learn more about advanced placement for this program.

$1,000 Scholarships Available!

$1,000 scholarships are available for new first-semester, full-time students enrolled in CVTC’s Advanced Machine Tool Technology program! All you need to do is successfully complete your first semester with 90% attendance and a 3.0 GPA. This scholarship is funded by Gene Haas Foundation for CVTC Advanced Machine Tool Technology Students.

To learn more, call 715-833-6300.

Earn credit for prior learning! Do you have previous educational or work experience in the field? You could be eligible to receive credit for prior learning.

Career Opportunities

CNC Machine Operator

CNC Machinist

Machinist

Graduate Employers

Advanced Laser Machine

Michaud Machining

Thomas Precision

Riverside Machine & Engineering

Just the Facts

Machine Tool Operator

31 Credit Technical Diploma

Program Length

One Year

Delivery Method

Face-to-Face

Program Location

Eau Claire

Start Months

August

Learn more about the cost of attendance.

Term 1

$ 3,065

Term 2

$ 3,332

Materials

$ 1,422

What are estimated program costs? Estimated Total: $7,819

Program Outcomes

CVTC graduates are ready for the workforce. Each year, we send our graduates the Graduate Follow-Up Survey asking several questions related to employment. Here are the program outcomes and job data.

// Program Scorecard$43K* Yearly Salary

Machine Tool Operator professionals make an average starting salary of $43,341.

67% Employed

67% of our recent Machine Tool Operator graduates got a job in the industry.

397 Regional Jobs

There are 397 job openings in the CVTC district for the Machine Tool Operator industry.

* This wage is not specific to CVTC graduates. Wage estimates are based on entry-level positions and are gathered from Lightcast which is an economic modeling software that blends historical and projected industry and occupation trends within CVTC's 11-county district. Wage estimates are based on Occupational Employment Statistics and the American Community Survey.

Transfer

Credits to Other Institutions

Should you choose to continue your education after you leave CVTC, we have agreements in place with several institutions to ensure an easy transfer.

Program Courses

These are a few of the courses you will take in this program. Courses and the recommended sequence change from year to year; once you are enrolled in a program at CVTC you will be given a recommended course sequence that outlines what courses you should take and the order in which to take them.

You may search for available courses. If you are ever unsure of what courses to take, talk to your academic advisor. If you are looking for course information for previous years, check out our past catalogs.

Here are a few of the courses you can take in the Machine Tool Operator program.

Sample Courses

Materials for Machinists

During this course individuals will learn the terminology relating to the mechanical, physical, and chemical properties of materials used for Machine Tool Technics. Materials covered will be the classification of steel, cast iron, aluminum, copper, and polymers. Lab activities include hardening, annealing, case hardening, destructive test, non-destructive test, casting molding, welding, and gluing of materials.

MT Blueprint Reading and GD&T

Introduction of engineering language used on blueprints; interpretation of blueprints; blueprints and understanding manufacturing processes and communication between product design and machinist - manufacturer.

CNC Mill Programming Theory

In this course students will acquire knowledge and skills in CNC Mill programming concepts. Students will develop and apply manual G & M code programming skills in linear and circular interpolation, canned cycles, cutter compensation techniques, and applications using sub-program and sub-routines. Math concepts will be applied to find Cartesian coordinates for part geometry.

Request More Information

Please provide your contact information and an Admissions Advisor will get back to you ASAP with more information about this program.

We will never share or sell your information outside of CVTC. We may, on occasion, contact you regarding relevant services, events, and materials. You may opt out at any time. View our privacy policy to understand how we collect and use your information.

Your future is waiting…Are you ready to get started?

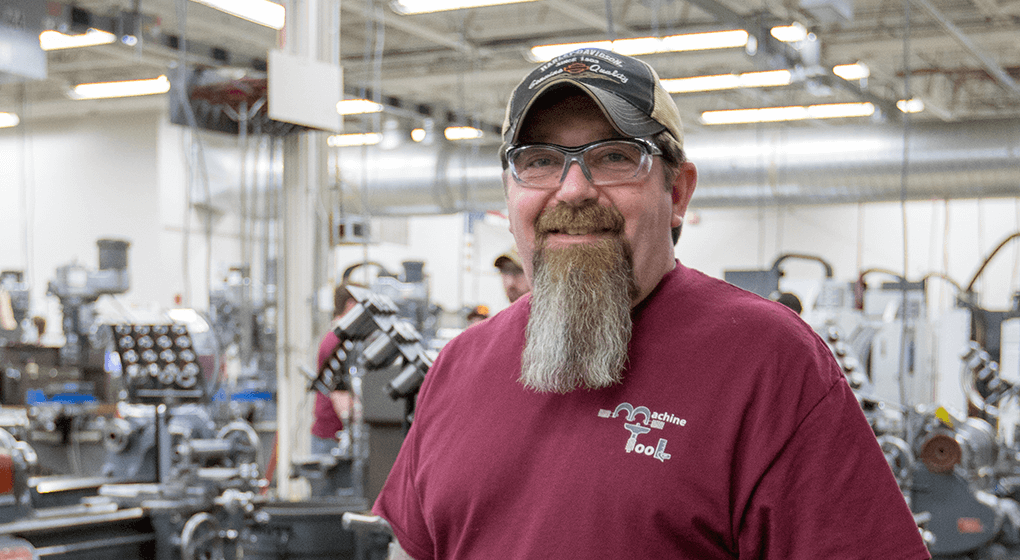

Apply NowStudent Testimonial

My shop teacher back in high school told me about the program and I tried it out, but because of certain circumstances, it didn’t work out. I joined the army, stayed 20 years, and came back here.

Travis

Machine Tooling Technics Student

Related Programs & Certificates

Whether you're looking to continue your learning to another program or to gain continuing education credit, CVTC offers a variety of learning opportunities for students.

Degrees & Diplomas

Automotive Maintenance Technician, Technical Diploma

Mechatronics Specialist, Associate Degree

Certificates

Continue Your Learning

CVTC can help you achieve your learning goals whether you are looking to advance your career or enrich your personal life.

// Explore Continuing Ed OpportunitiesUnsure of which program you'd like to go into? Learn more about our Career Assessment to help narrow down your options.

A Program You Can Trust

Program Accreditation

CVTC is a NIMS accredited organization for Machine Tool Operator. NIMS accreditation is the nation's only distinction for excellence in manufacturing training based on NIMS industry-written, industry-approved standards. Accredited programs demonstrate the ability to produce skilled, work-ready individuals that fulfill industry's 21st century workforce needs.

Student Learning Outcomes

A Student Learning Outcome refers to the specific skills, knowledge, or abilities that students are expected to demonstrate upon successful completion of an academic program or degree.

Students will:

- Apply basic safety practices in the machine shop

- Interpret industrial/engineering drawings

- Apply precision measuring methods to part inspection

- Perform basic machine tool equipment set-up and operation

- Perform programming, set-up and operation of CNC Machine Tools

Additional Admissions Resources

Admission Requirements

Each program requires specific requirements a student must meet to be considered for admissions to this program.

// View Admission RequirementsAdvanced Placement

This program has an advanced placement option. Eligibility for advanced placement requires students to meet additional requirements.

// View AP Admission RequirementsAdvising Tips

We have compiled helpful tips and general information for students in this program.

// View Advising Tips